Operating Principle of

Hänel Rotomat® Storage

Intelligent Rotary Storage Technology

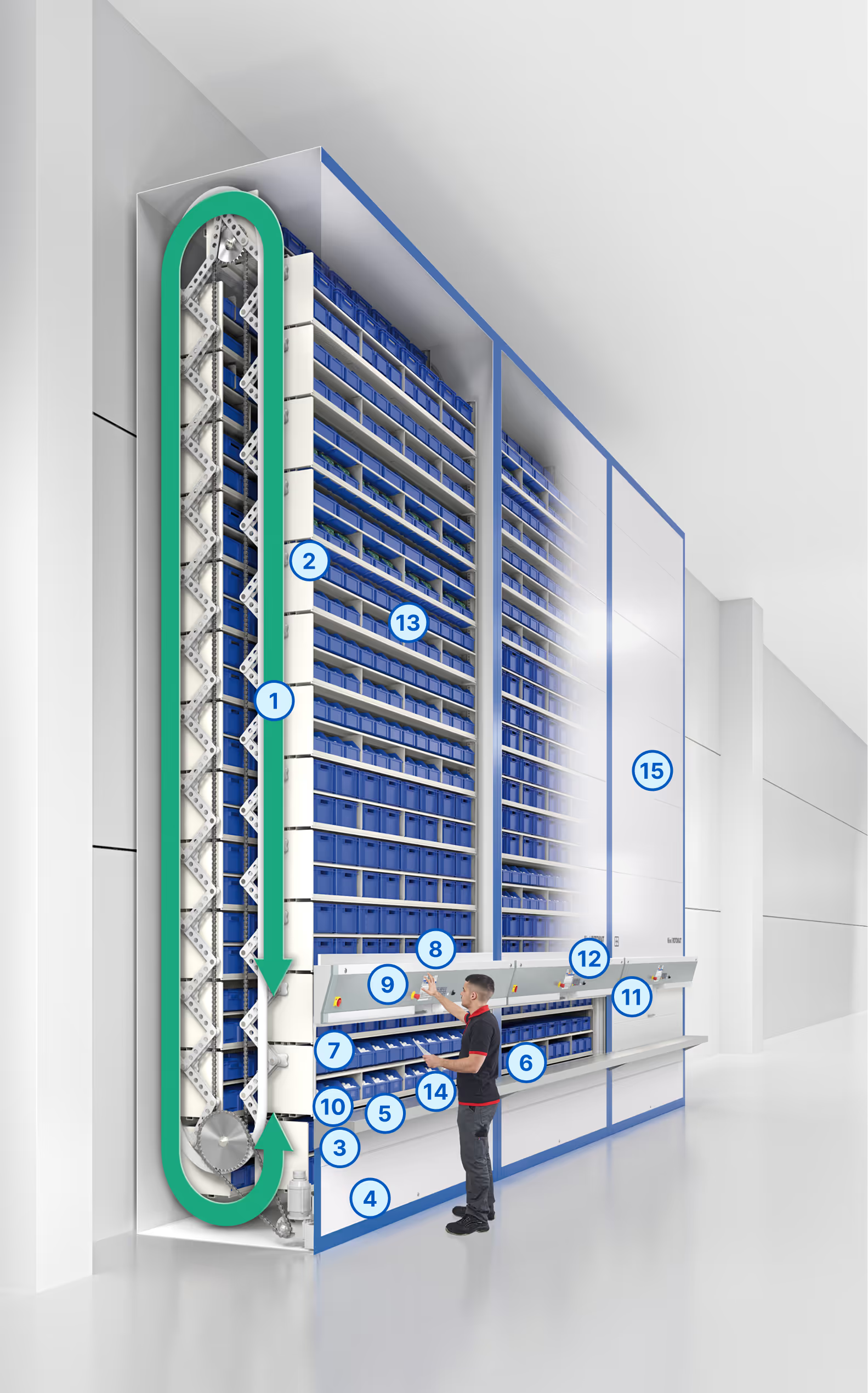

The Hänel Rotomat® is a vertical carousel storage system that maximizes storage capacity while minimizing floor space requirements. Operating on the proven Ferris wheel principle, this automated system brings stored items directly to the operator at an ergonomic working height. With space savings of up to 85% compared to traditional storage methods, the Rotomat® features a self-supporting steel construction, intelligent microprocessor controls, and comprehensive safety systems. Perfect for industrial applications requiring efficient storage and retrieval of tools, components, and materials across manufacturing, automotive, and logistics sectors.

The principle of the Hänel Rotomat® storage carousel

Vertical carousel technology – simply brilliant

Carrier suspension

on 4-point sliding carriage principle

Internal drive system

with two motors

Soft start

with pole-switching motors

Access point with V2A work counter

wear-resistant

Ergonomic safety threshold switch

optimal personal protection

Light barrier curtains

compliant with DIN EN 15095

Hänel microprocessor controllers

and Hänel software solutions

Wiring box

with centrally housed electrical components

Multifunction positioning system

for accurate positioning of shelf levels

Lockable sliding doors

for inventory protection

Hänel EcoLoad®

for balanced and efficient load distribution

Multifunction carriers

with variable dividers and inserts

Compartment indicators

for error-free retrieval

Environmentally friendly powder coating

50% more abrasion-resistant

Let Experts Help You Make the Right Choice

Smart automation saves space, cuts costs, and boosts efficiency — but choosing the right system can be complex. Our specialists will guide you to the best solution for your business.